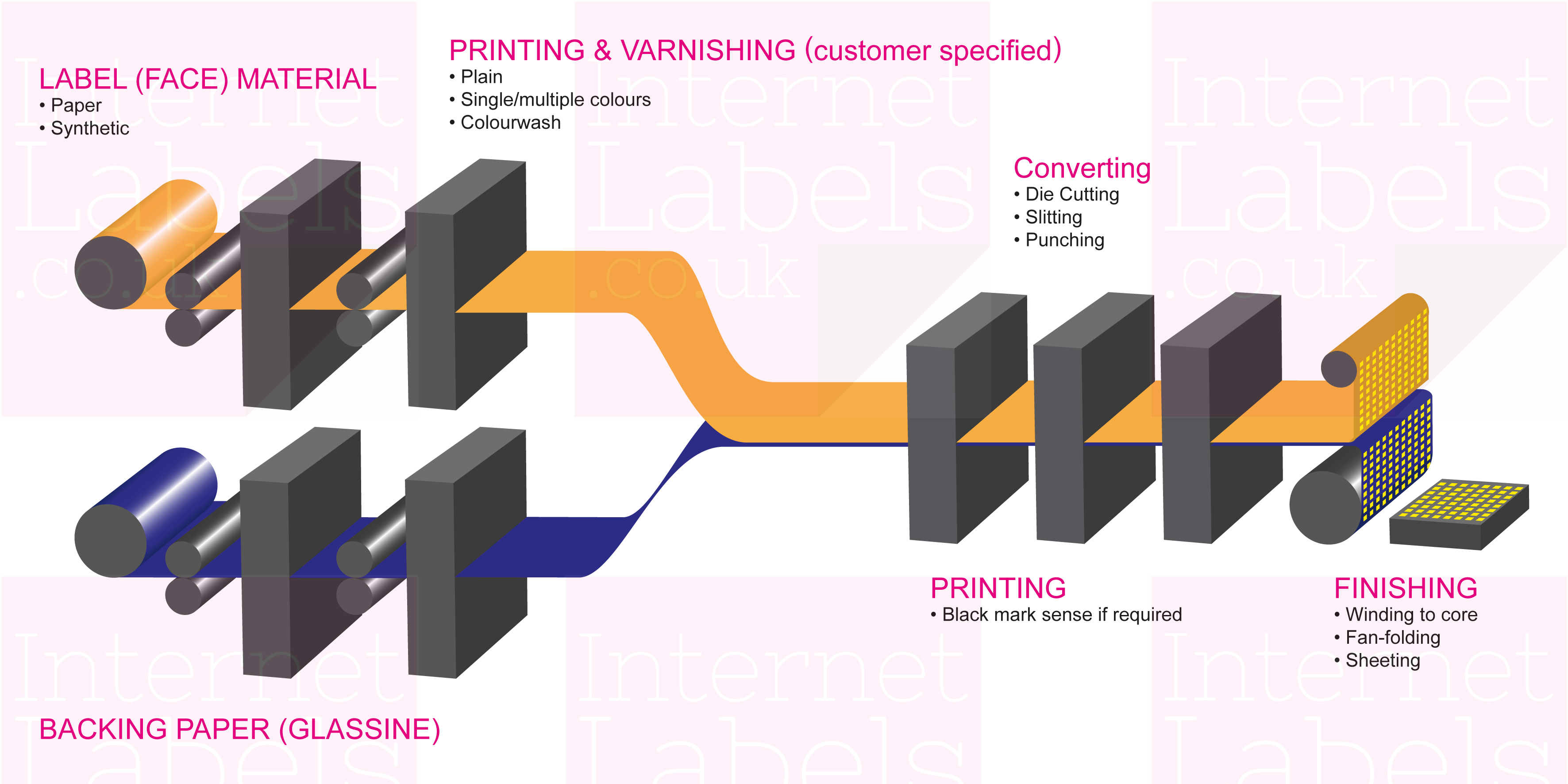

Adhesive labels for barcoding and product identification - what are they made from?

An adhesive label is made up from at least 3 layers and often more.

Backing Paper

The backing paper or base layer (often referred to as glassine) has a silicone coating to allow adhesive to stick to it but be easily removed. On roll fed labels it is important that the backing paper does not extend too far past the label (face paper) left and right margins. Overly wide backing paper reduces the effective print width of the printer by creating unnecessarily large left hand margin or indent. A 2-3mm margin to each side is usually ample. Glassine can be recycled and specialist companies can arrange collection from users premises.

Adhesive

This layer provides for the adherence of the label to a surface. It is important to use the correct adhesive for the job in hand. Permanent adhesive is intended to ensure the label remains in position for as long as possible and usually the label and/or product surface will be damaged if removal is attempted. Peelable adhesive, if correctly specified, allows the label to be peeled from the surface it is applied to with no damage to the label, and little if any remaining residue on the applied to surface. Soluble adhesive (beer kegs, food trays etc) high tack adhesive (rubber, rough/dirty surfaces etc.) and freezer adhesive (very cold, potentially damp surfaces, including blast freezing) are just some of the alternative adhesive types available to label buyers.

For the adhesive to perform to its best capabilities certain parameters including environmental (temperature, moisture) need to be considered as well as the surface (energy) of the receiving surface. Plastics and rubber can be contaminated with mould release agent, metal may be rusty, damp or greasy and cardboard (particularly recycled cardboard) may be dusty. These issues can usually be dealt with if the correct adhesive is specified. The application temperature of the receiving surface is also a consideration as is the available time to allow the adhesive to cure (set) before changing the temperature or environmental conditions. Some adhesives may require more time than others to achieve maximum effectiveness and resistance to changing environmental conditions and therefore it is important to discuss any unusual requirements in detail with an expert advisor.

Label adhesives are normally rubber or acrylic based and will vary between direct thermal/thermal transfer and laser. Food safe adhesives and accreditations to various standards such as EU food regulation (food contact) 1935/20 04/EC, Isega, ISO 22000:2005, FDA, are available to suit multiple compliance requirements. All Internet Labels stock labels come with permanent and food safe adhesive suitable for product and carton labelling

Label (face) Material

There are 100’s of face material types. Paper (in scores of configurations) is the single biggest group however synthetics, metallised and card are also common. Face paper is often coated (more detail below) for better performance and the face material properties can make the difference between printing a good or bad barcode. Internet Labels stock labels feature machine coated industry proven face paper to produce guideline compliant barcode labels.

Synthetics including polypropylene (PP), polyethylene (PE) and polyesters (including metallised for serial plates) are popular choices when considerations such as recycling in situ and extended longevity are required. For specialised non-paper labels it is best to check with your supplier before ordering. Internet Labels offers a personalised quotation and technical information service as well as free samples for customer to test.

Top Coat

A vital part of the label, and one which can be optional from some suppliers. This microscopically thin layer is often key to printing a good barcode. It can also be the difference between a long lasting print head and premature failure. Top coats can tailored to the performance characteristics and print technology required. Thermal transfer and direct thermal labels feature different topcoats for optimum compatibility.

Of particular importance for direct thermal labels (which are printed without the print head protecting properties of a printer ribbon) is a special top coating designed to isolate the expensive print head from the abrasiveness of the label material. Although paper may often appear to be smooth continuously passing labels over the protective ceramic coating of a print head can produce visible degradation in only a few days. The few pence per thousand which can be saved by omitting a protective top coat can be totally offset by the extended print head life a good quality top coating can provide. Internet Labels only stocks top coated direct thermal labels.

For more information, samples and advice visit www.internetlabels.co.uk